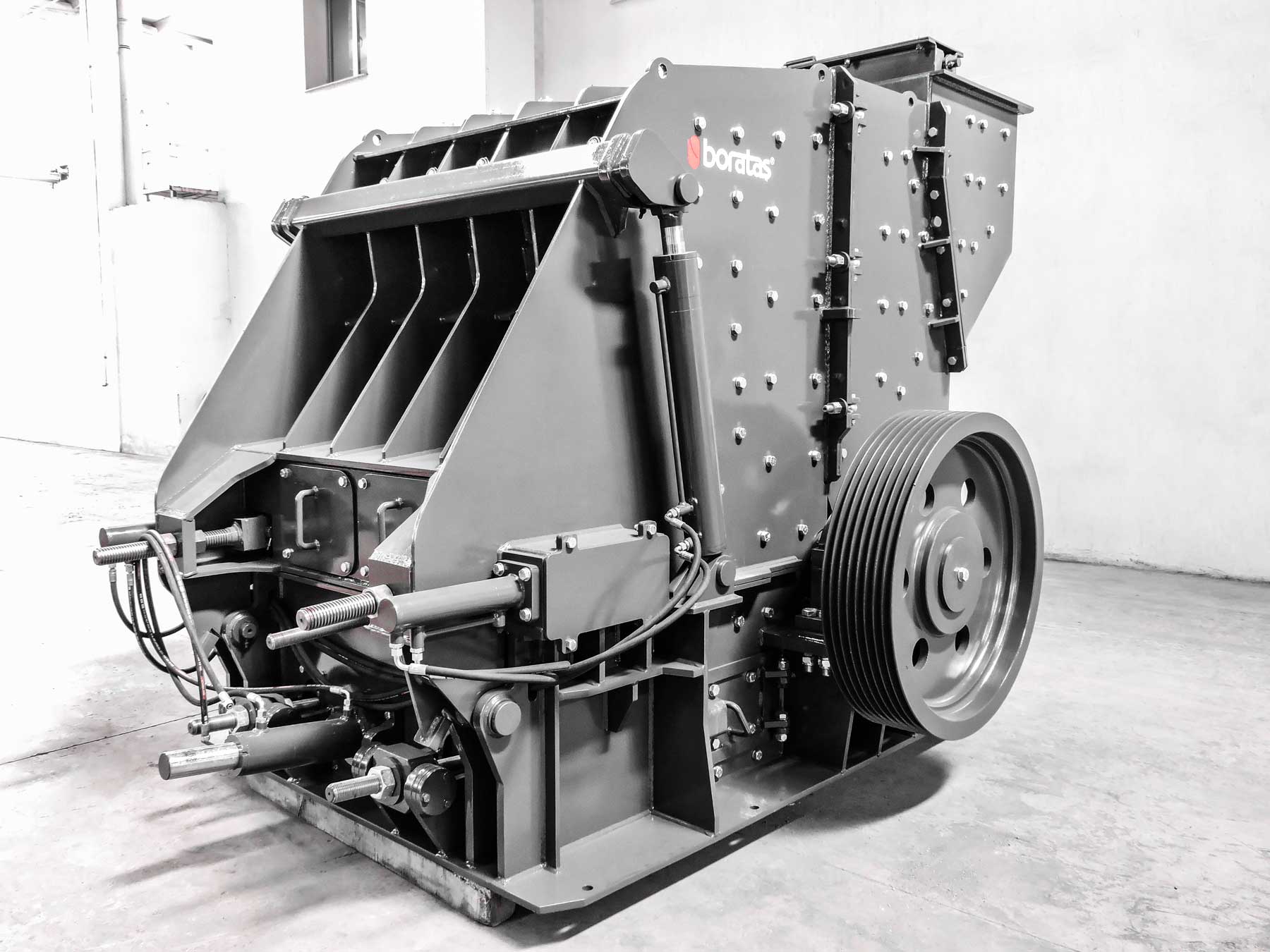

Description

Borataş Machine DMK series crushers are commonly used for medium and higher hardness materials like limestone, granite, basalt, etc. for asphalt and concrete.

High capacity, oversize feeding, cubical product, high reduction ratio, low operating and investment cost makes these crushers the most efficient secondary crushers in their application field.

Crusher body is composed of three main parts, of which, hydraulically rotating upper body, stationary lower body could easily be dismantled.

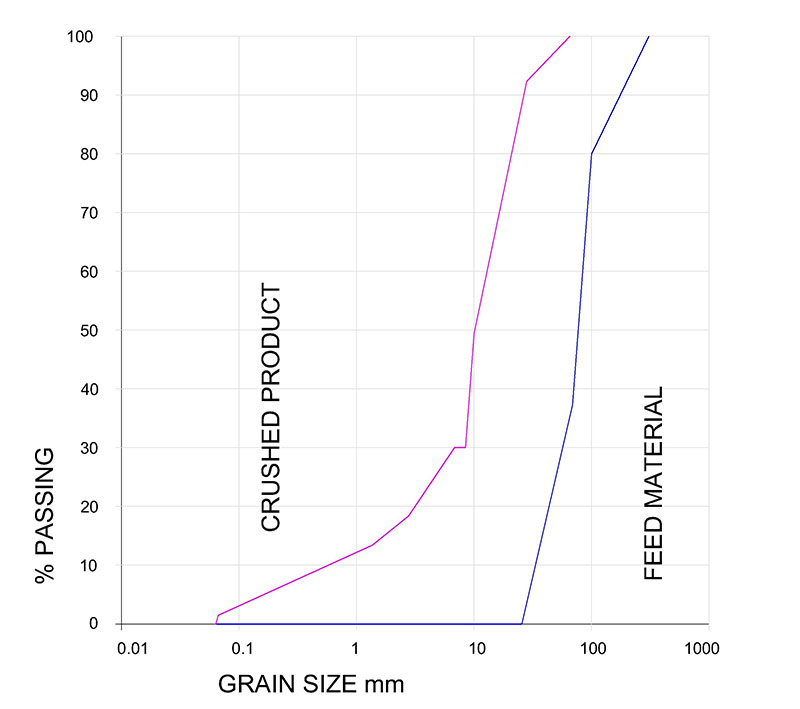

Crushing Takes Place In Three Successive Zones In The Crushing Chamber / Impact Zones

- Zone 1: Primary crushing takes place throwing the material by blow bars through upper crushing plates.

- Zone 2: The material passing through this zone, a higher rate of reduction occurs accelerated by blow bars grinding carriages.

- Zone 3: Shaping zone and may be called the grinding zone. The length of the grinding path affects the rate of coarse grain and cubicity.

In comparison with other crushing machines,the DMK series of impact crushers are some basic advantages. Such as:

- High degree of comminution

- High reduction ratio due to triple-stage crushing

- Selective grinding

- Better product quality

- Better grain shape / higher cubicity

- In the recycling process excellent resistance in concrete loosening reinforcement

- Low space requirement

- Low energy requirement

- Low investment costs

- Easy maintenance due to the simple design

- Low wear costs

- Flexibility in variable performance requirements

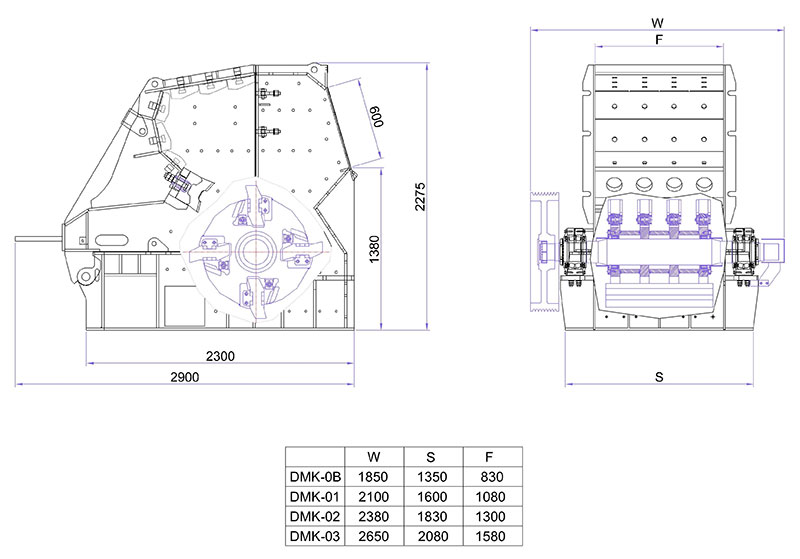

Stationary Tertiary Impact Crusher TDK series models and data- General Table

| Model | Rotor Size (mm) |

Material Size (mm) max |

Capacity (t/h) min-max |

Engine (kW) |

Weight (kg) |

|---|---|---|---|---|---|

| DMK0B | Ø 1,120 x 750 | 450 | 100-140 | 110 | 11.500 |

| DMK01 | Ø 1,120 x 1,000 | 450 | 130-200 | 160 | 14.500 |

| DMK02 | Ø 1,120 x 1,250 | 450 | 170-250 | 200 | 18.100 |

| DMK03 | Ø 1,120 x 1,500 | 450 | 250-350 | 250 | 20.800 |

* Machine weights include flywheels, rotor, and upper chute, excludes motor, chassis, and lower chute

** Capacity figures given in the table above are approximate and are to give an idea about the expected quantities where the density is 1600 kg/m³ clean and dry limestone fed into the crushing chamber at maximum sizes without any difficulty. These capacity rates vary depending on the appropriate selection and operation of feeder, conveyor, other equipment, etc., and also permanent regular feeding.

CAPACITY FIGURES

Download The Boratas Stationary Crushing and Screening Machines PDF Catalogue

' Boratas Stationary Crushing and Screening ' PDF Catalogue.

Related Videos

Boratas DMK Impact crusher is used as a secondary crushing stage in this plant.

360 3D view

Click and Drag to left/right inside the box below, in order to view 360 degrees render-image.