Description

The secondary impact crusher is one of our most advised machines due to its high efficiency and reliability. These machines can crush materials such as asphalt or medium and high hardness concrete aggregates. They are also characterized by a large discharge opening allowing a perfect flow of materials and an outstanding crushing.

Used in the secondary crushing study, these machines can produce high-quality products with a cubic shape and the desired dimensions which are easily arranged thanks to the hydraulic system.

Impact crushers are designed to last a very long time minimizing the need of maintenance, while maximizing performance, whether in the primary, secondary or tertiary.

Impact crushers are defined by a combination of high inertia rotor, wear-resistant materials, and a well-sized crushing chamber. This combination allows a good production rate while producing a fine and high-quality product.

The fact that the impact crushers are used in all crushing stages shows their importance for Boratas. We recognize that these machines are widely demanded and that our customers expect high quality. This motivated us to produce a machine able to exceed our customers’ expectations.

The components of our machines, as well as the materials used, are the reason for their low need for maintenance. The rotor, which is made of cast steel, is very robust, the hammers are made of alloyed manganese which strengthens its last and increases its long life.

Characteristics of the Impact Crusher

- High reduction rate

- Low investment cost

- Low operating cost

- Simple size setting

- Large discharge opening

- Use in fixed and mobile installations

Advantage

- Easy maintenance

- Easy replacement of worn parts

- Long life expectancy

- Multiple use of blow bars (4x)

Stationary Primary Impact Crusher PDK series models and data - General Table

| Model | Rotor Size (mm) |

Material Size (mm) max |

Capacity (t/h) min-max |

Engine (kW) |

Weight (kg) |

|---|---|---|---|---|---|

| SDK01 | Ø 1,100 x 1,000 | 300 | 100-200 | 160-200 | 12.600 |

| SDK02 | Ø 1,200 x 1,250 | 400 | 150-300 | 200-250 | 16.1400 |

| SDK03 | Ø 1,300 x 1,500 | 400 | 200-400 | 250-315 | 19.900 |

| SDK04 | Ø 1,500 x 2,000 | 400 | 300-500 | 2 x 315 - 2 x 355 | 26.000 |

* Machine weights include flywheels, rotor, and upper chute, excludes motor, chassis, and lower chute

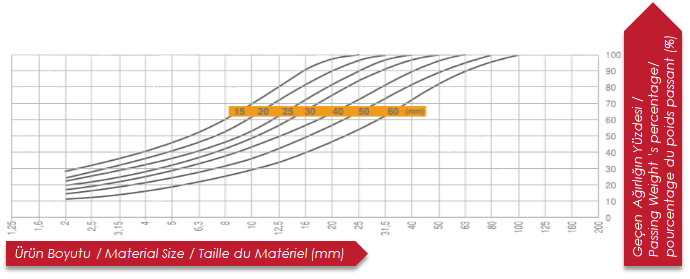

CAPACITY FIGURES

Download The Boratas Stationary Crushing and Screening Machines PDF Catalogue

' Boratas Stationary Crushing and Screening ' PDF Catalogue.

Related Videos

Crushing and Screening Plant with a capacity of 550 tons per hour located in Denizli/Turkey. Machines used in this plant are primary impact crusher, secondary impact crusher, tertiary impact crusher, and vibrating screens which are products of Boratas Machinery.

360 3D view

Click and Drag to left/right inside the box below, in order to view 360 degrees render-image.