Description

Primary impact crushers are characterized by a high capacity and good performance. They can crush materials with medium or low hardness and can yield a very fine production compared to jaw crushers. Accordingly, It is possible in some cases to produce a product with the desired dimensions without the need of a secondary crusher.

Impact crushers are designed to last a very long time minimizing the need for maintenance, while maximizing performance, whether in the primary, secondary or tertiary.

Impact crushers are defined by a combination of high inertia rotor, wear-resistant materials, and a well-sized crushing chamber. This combination allows a good production rate while producing a fine and high-quality product.

The fact that the impact crushers are used in all crushing stages shows their importance for Boratas. We recognize that these machines are widely demanded and that our customers expect high quality. This motivated us to produce a machine able to exceed our customers’ expectations.

The components of our machines, as well as the materials used, are the reason for their low need for maintenance. The rotor, which is made of cast steel, is very robust, the hammers are made of alloyed manganese which strengthens its last and increases its long life.

Characteristics of the Impact Crusher

- High reduction rate

- Excellent cubic form

- Less sensitivity against sticky substances

- Versatile and can be used in quarries, cement industry, concrete recycling etc.

Advantage

- Easy and fast installation

- Mechanical reliability

- Ease of use

- Use in fixed and mobile applications

Stationary Primary Impact Crusher PDK series models and data- General Table

| Model | Rotor Size (mm) |

Material Size (mm) max |

Capacity (t/h) min-max |

Engine (kW) |

Weight (kg) |

|---|---|---|---|---|---|

| PDK01 | Ø 1,200 x 1,000 | 500 | 150-200 | 160-200 | 14.900 |

| PDK02 | Ø 1,300 x 1,250 | 600 | 200-300 | 250-315 | 19.100 |

| PDK03 | Ø 1,400 x 1,500 | 900 | 250-600 | 315-355 | 26.600 |

| PDK04 | Ø 1,600 x 2,000 | 1000 | 400-1000 | 2 x 315 - 2 x 355 | 45.000 |

| PDK00 | Ø 1,100 x 1,000 | 400 | 160-200 | 160-200 | 10.700 |

| PDK02-M | Ø 1,200 x 1,250 | 600 | 150-300 | 200-250 | 14.400 |

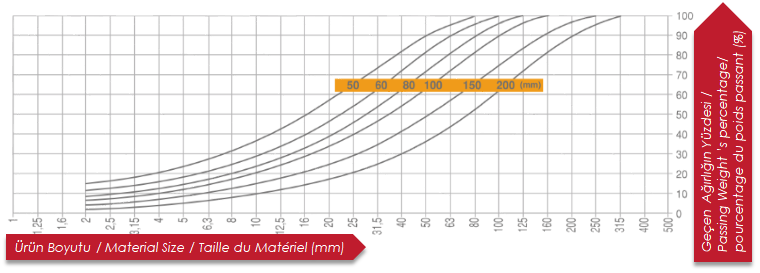

CAPACITY FIGURES

Download The Boratas Stationary Crushing and Screening Machines PDF Catalogue

' Boratas Stationary Crushing and Screening ' PDF Catalogue.

Related Videos

Primary Impact Crusher is used as the first stage in this plant

360 3D view

Click and Drag to left/right inside the box below, in order to view 360 degrees render-image.