Description

Unlike other crushers that use metal components, our vertical axis mill uses the fed rocks to break itself, thus minimizing operating costs considerably compared to other crushers. The output result of these machines is of high quality with an improved cubic shape, thus making the product adequate and more demanded by the construction industry.

These crushers are used in the last stages of crushing, in other words in the tertiary and quaternary stages.

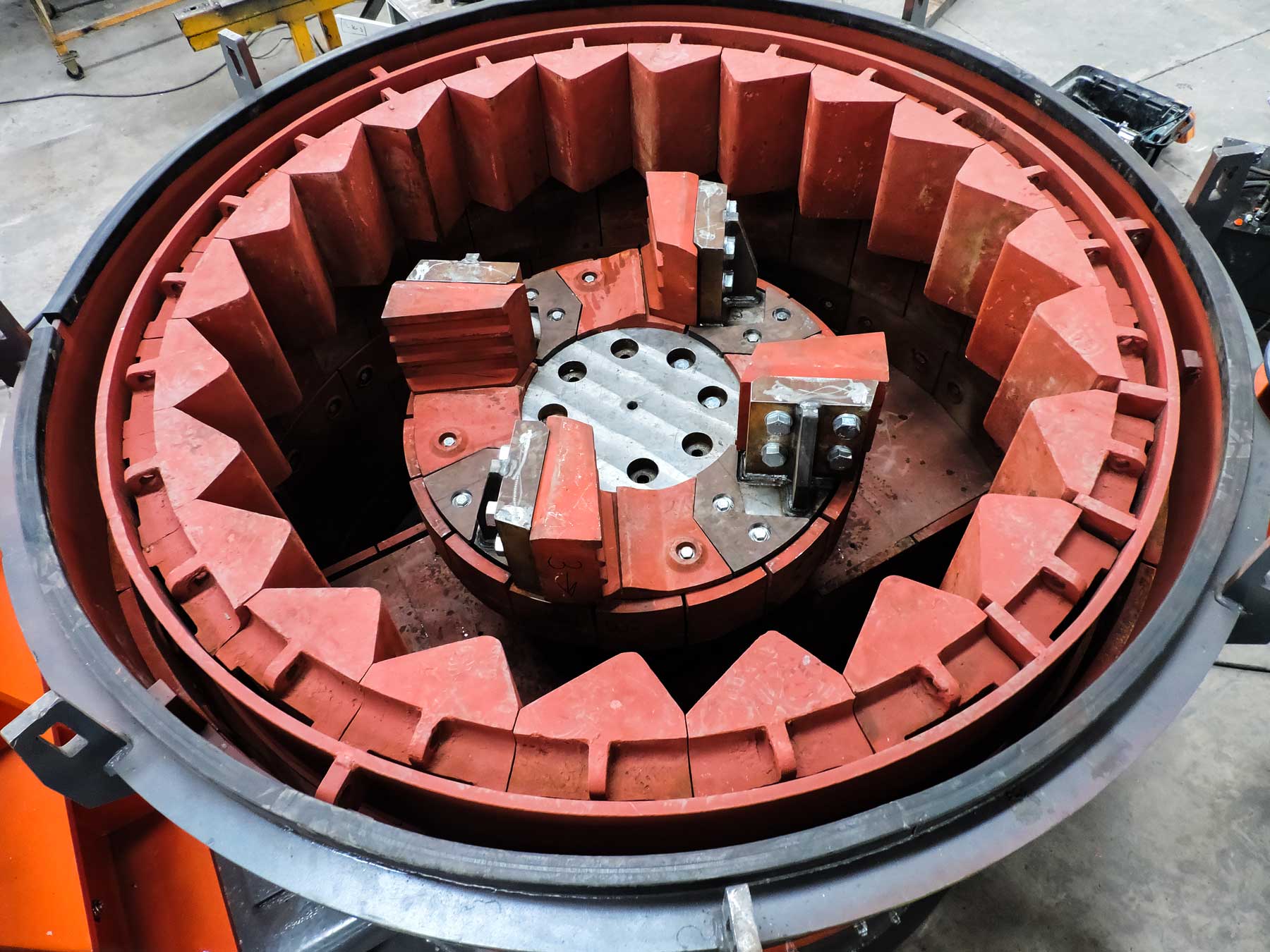

Process of the vertical axis impact crusher

The shaft is placed inside a chamber that contains a special crushing chamber having a rock-lined ring. The material is fed into the top of the chamber with the primary amount of the feed entering the top of the rotor. The rotor throws the material centrifugally out towards the crushing chambers at extremely high speed. A secondary amount of material feed falls into the accelerated primary feed at the crushing chamber. Thus all the material is reduced in a highly turbulent material cloud contained within the crushing chamber. Reduction occurs by impact, attrition, and abrasion.

The components of our machines, as well as the materials used, are the reason for their low need for maintenance. The rotor, which is made of cast steel, is very robust, the hammers are made of alloyed manganese which strengthens its last and increases its long life.

Advantage

- Production of a product with a superior cubic form

- Ability to control product ranking by cascade and top speed

- Low wear costs due to the unique grinding of stone to stone

- Accepts fine materials in the diet

Stationary Vertical Shaft Impact Crusher (opened) VSI series models and data- General Table

| Model | Rotor Size (mm) |

Material Size (mm) max |

Capacity (t/h) min-max |

Engine (kW) |

Weight (kg) |

|---|---|---|---|---|---|

| VSI1000 | Ø 1,100 | 80 | 100-350 | 160-200-250 | 14.500 |

| VSI1200 | Ø 1,200 | 80 | 200-500 | 250-315-355 | 19.000 |

* The vertical shaft impact crusher functions based on the rock-to-rock crushing. This type of crusher is used for crushing abrasive stones such as creek material, andesite, basalt, granite, etc. Finally, the crushed materials acquire a cubic form.

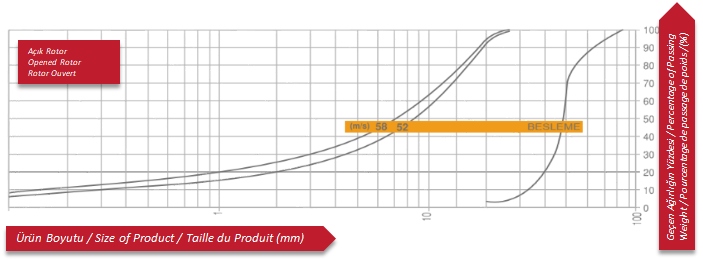

CAPACITY FIGURES

Download The Boratas Stationary Crushing and Screening Machines PDF Catalogue

' Boratas Stationary Crushing and Screening ' PDF Catalogue.

Related Videos

Boratas VSI performing in plant

Boratas Machinery rock-to-rock type Vertical Shaft Impact (VSI) crushers are the best solution for tertiary and quaternary crushing. The VSI consists of a vertical rotating shaft to which a special horizontal rotor is attached.

360 3D view

Click and Drag to left/right inside the box below, in order to view 360 degrees render-image.