Description

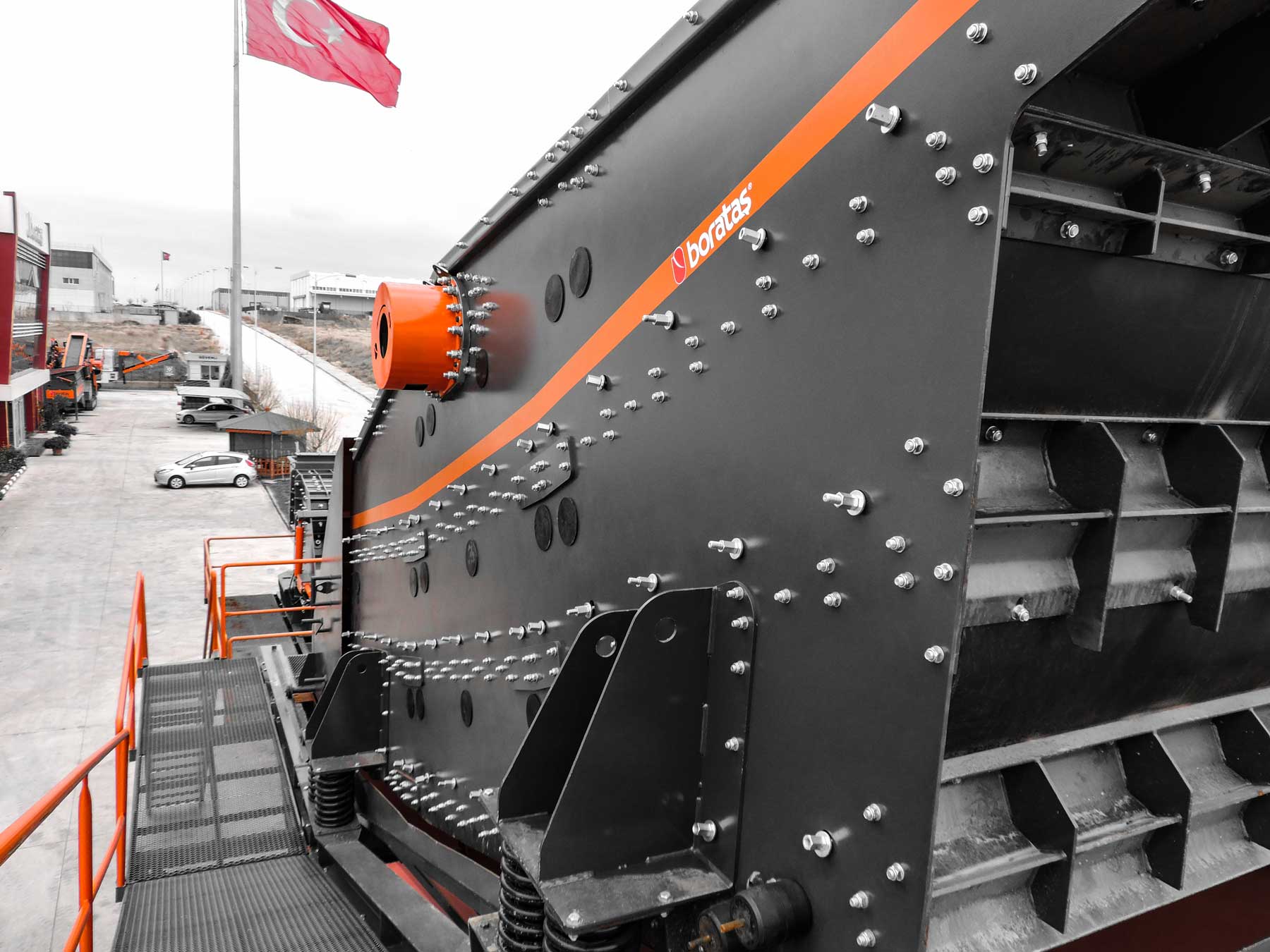

Boratas multiple slope screens are designed and produced to have three different slopes. At the feed section, the slope is steep which allows a fluent and quick material flow. This greatly facilitates the flow and classification of materials on the screen. The slope is reduced at the end of the discharge to hold the materials longer on the surface of the screen to increase the efficiency of the screen.

Boratas screens can have up to three decks depending on the number of ending products the customer wants. They are powered by a separate electric motor and are mounted with a shaft on their main body which contains special bearings and two counterweights. The movement of materials on our vibrating screens is circular and fluent without any disturbance

The use of a high-quality and efficient vibrating screen is a prerequisite, as the latter greatly influences the classifying of the crushed product, which is the most important step in a crushing system.

The capacity of multi-slope screens is 20-30% greater than other screens with similar dimensions.

Stationary MultiSlope Screen BKE series models and data- General Table

| Model | Dimensions (mm) |

Decks |

Engine (kW) |

Weight (kg) |

|---|---|---|---|---|

| BKE202 | 1,800 x 6,000 | 2 | 15 | 7,100 |

| BKE203 | 1,800 x 6,000 | 3 | 22 | 9,600 |

| BKE302 | 2,000 x 6,000 | 2 | 22 | 11,000 |

| BKE303 | 2,000 x 6,000 | 3 | 30 | 13,250 |

* Given, approximate, weights include only the screen body. This does not include the front chute, lower trough, and chassis.

Download The Boratas Stationary Crushing and Screening Machines PDF Catalogue

' Boratas Stationary Crushing and Screening ' PDF Catalogue.

Related Videos

BKE MultiSlope Screen is installed in this plant, however, it's covered in a container to reduce dust.

Crushing and Screening Plant with 250-275 tph

Crushing material : Bazalt

360 3D view

Click and Drag to left/right inside the box below, in order to view 360 degrees render-image.