Description

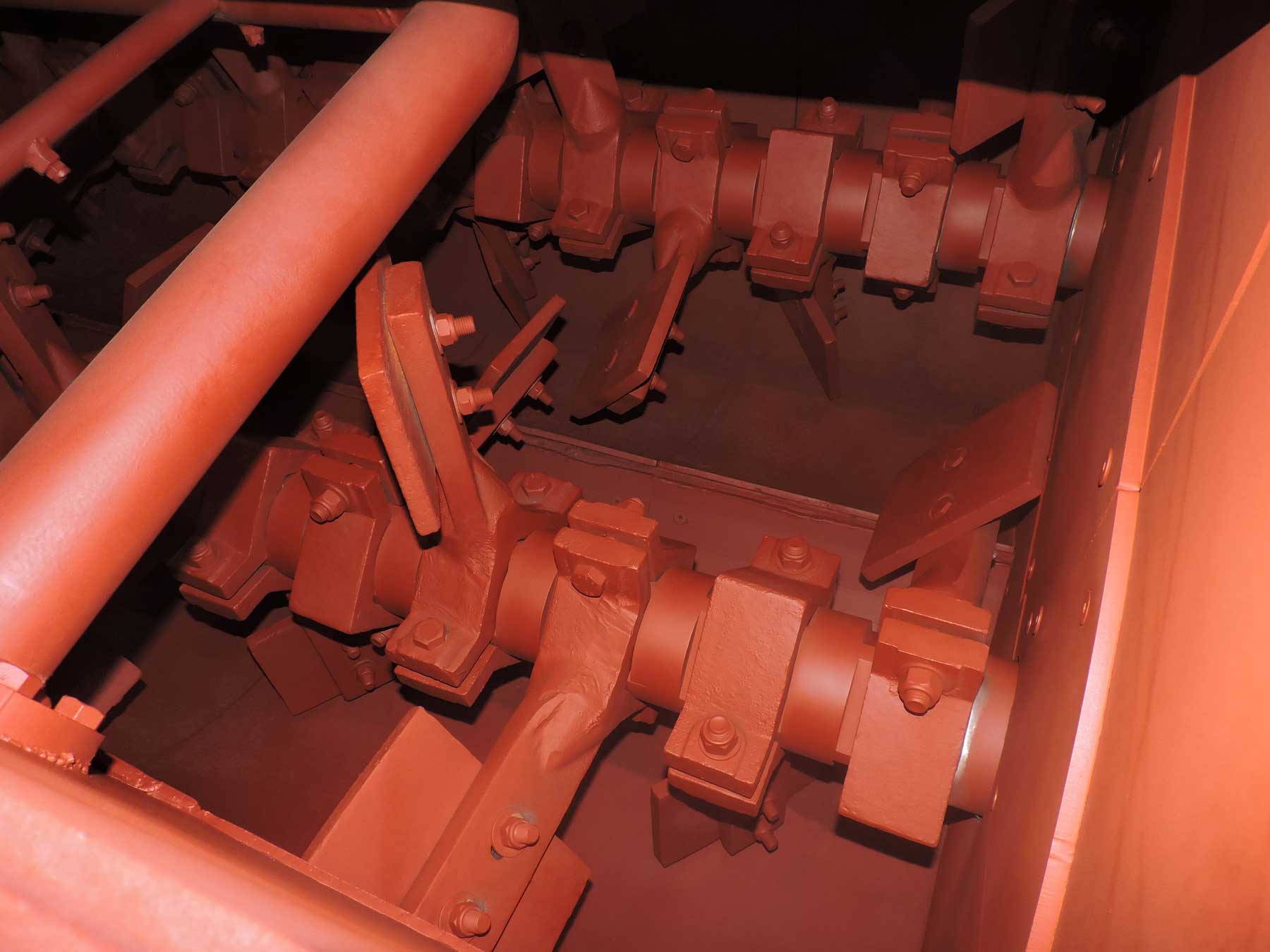

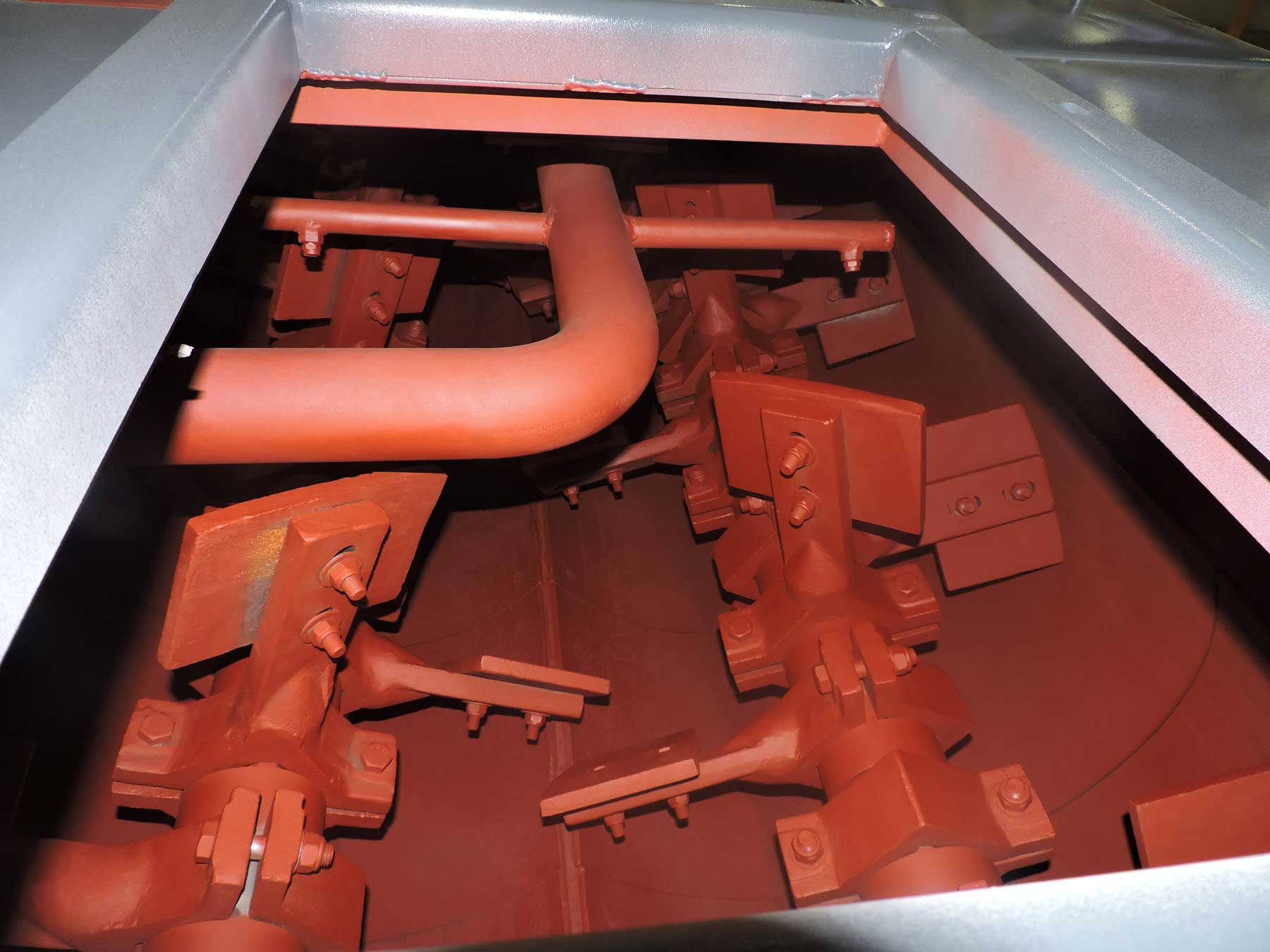

BMS Mixers are used before the asphalt road infrastructures are used to produce a homogeneous mixture of crushed material. Paddle mixer is the mixer is discharged to the material prepared in the desired proportions and uniformly mixed by moving towards the discharge opening. Through the introduction of water during the mixing process, the desired amount of water is added to the mixture.

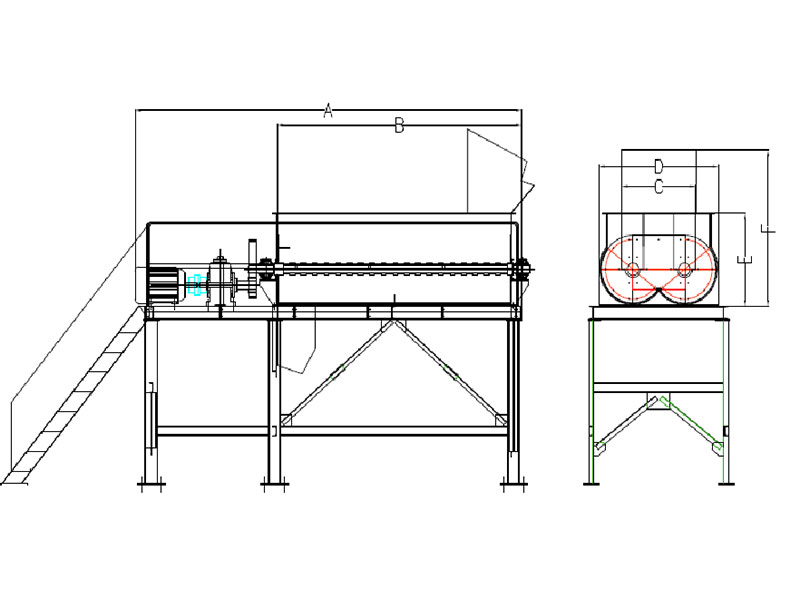

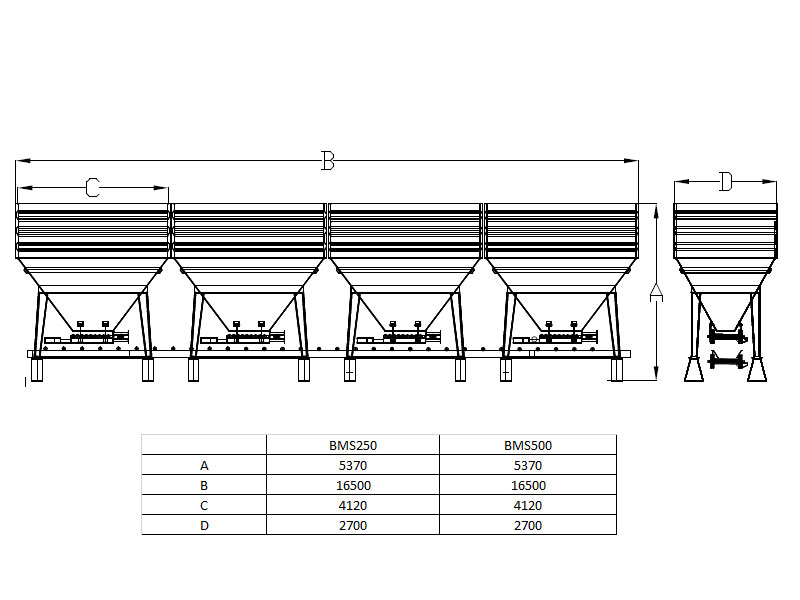

Borataş aggregate bunkers are produced in 2 types with the capacity of 250-300 t/h and 450-500 t/h, depending on the asphalt-construction sites' demand. The group of 4 aggregate hoppers is completed with feeder belts and the material flow is adjusted mechanically.

Stationary Mechanical Stabilization BSM series models and data- General Table

| Model | Capacity (t/h) |

Hopper volume (m³) |

Feeding conveyors (mm) |

Collecting conveyor (mm) |

|---|---|---|---|---|

| BMS 250 | 250 | 4 x 17 | 600 x 1,500 | 800 x 14,000 |

| BMS 500 | 500 | 4 x 17 | 800 x 1,500 | 1,000 x 14,000 |

CAPACITY FIGURES

Download The Boratas Stationary Crushing and Screening Machines PDF Catalogue

' Boratas Stationary Crushing and Screening ' PDF Catalogue.

Related Videos

Crushing and Screening Plant with 250-275 tph

Crushing material : Bazalt

360 3D view

Click and Drag to left/right inside the box below, in order to view 360 degrees render-image.