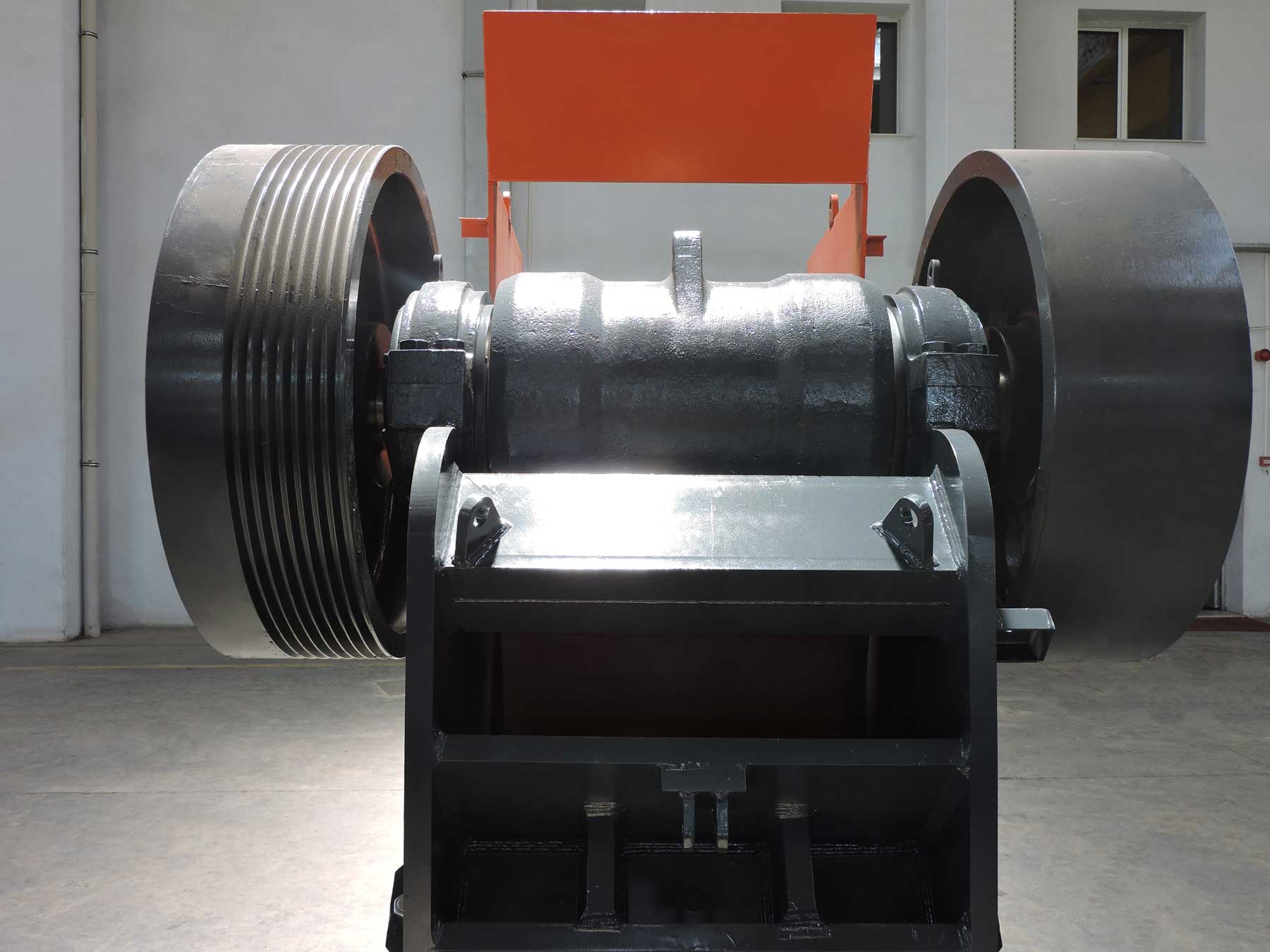

Description

Jaw crushers are commonly used in the primary crushing stage to obtain quarry aggregates, however, it is not uncommon to use them in the secondary stage as well. These machines are made to crush all kinds of stone, minerals, slag, etc ... no matter how sturdy and abrasive they are.

Jaw crushers are designed to increase the productivity rate to the maximum while minimizing costs. These are reliably made to bind and are easily maintainable.

The essential components of a jaw crusher are:

- The flywheel

- The pitman

- The rocking plate

- Fixed and mobile jaw

- Engine

- Spring

The crushing of the materials comes from the top/bottom movement of the swing jaw. This movement is achievable thanks to the eccentric movement of the axis connected to the flywheel. The toggle plate protects the swing jaw foreign material is found in the crushing chamber by breaking which stops the swing jaw, thus preventing damage.

Admission capacity

The design of the Borataş jaw crushers offers a deep enough feeding depth allowing a very high intake capacity as well as an impeccable flow of material without any problem, this is due to the dimensions of the feeding opening which is well balanced with the dimensions of these machines.

Maintenance

The parts subject to wear are easily replaceable which is why our machines are so easy to maintain.

In case of the unwanted presence of iron parts, the swing jaw is equipped with toddling plates to provide ease of breakage to protect the crusher from any damage. the toggle seats are designed to be easily replaced and not to be lubricated again.

Crushing chamber

In order to guarantee an optimal material flow in the grinding chamber, our engineers were able to find the optimum angle of inclination between the fixed and swing jaws. The angle of inclination Is very crucial since, if adjusted optimally, reduces the wear rate of the jaw crusher components, which means less maintenance cost and lost time.

Production and reduction ratio

The movement from the top to the bottom of the swing jaw presses the materials against the fixed jaw towards the bottom of the grinding chamber crushing it. This increases the reduction rate and guarantees a high production rate.

Characteristics of the Jaw Crusher

- Crushing of all kinds of materials and stones no matter how sturdy and abrasive they are

- Usable in mobile and fixed installations

- Applicable to the surface and in underground quarries

- Usable in the primary and secondary crushing operation depending on the size of the machine

Advantage

- High efficiency and durability

- High continuous crushing performance

- Easily maintainable

- High reduction ratio

Stationary Jaw Crusher BCK series models and data- General Table

| Model | Stage | Feeding Dimensions (mm) |

Exit Dimensions (mm) min-max |

Capacity (t/h) min-max |

Engine (kW) |

Weight (kg) |

|---|---|---|---|---|---|---|

| BCK02 | Primary | 610 X 380 | 40-150 | 20-110 | 30 | 6.000 |

| BCK03 | Primary | 900 X 650 | 60-200 | 50-250 | 75 | 11.000 |

| BCK07 | Primary | 1,100 X 850 | 100-200 | 100-300 | 132 | 27.000 |

| BCK10 | Primary | 1,200 X 1,000 | 120-250 | 300-700 | 160 | 45.000 |

| BCK11 | Primary | 1,300 X 1,100 | 150-300 | 250-650 | 200 | 55.000 |

| BCK04 | Secondary | 900 X 200 | 20-60 | 3-40 | 30 | 6.000 |

| BCK12 | Secondary | 1,100 X 350 | 20-100 | 30-250 | 75 | 11.000 |

* Machine weights include flywheels, rotor, and upper chute, excludes motor, chassis, and lower chute

** Capacity figures given in the table above are approximate and are to give an idea about the expected quantities where the density is 1600 kg/m³ clean and dry limestone fed into the crushing chamber at maximum sizes without any difficulty. These capacity rates vary depending on the appropriate selection and operation of feeder, conveyor, and other equipment, etc., and also permanent regular feeding.

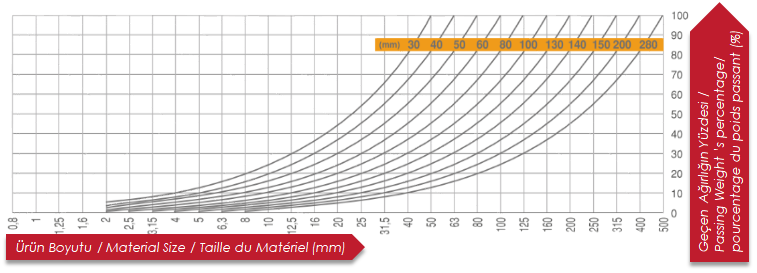

CAPACITY FIGURES

Download The Boratas Stationary Crushing and Screening Machines PDF Catalogue

' Boratas Stationary Crushing and Screening ' PDF Catalogue.

Related Videos

The essential components of a jaw crusher:

+ The flywheel

+ The pitman

+ Fixed and swing jaw

+ Electric motor

+ Spring

Jaw Crusher 1.300x1.100mm 450-600 ton/hour

360 3D view

Click and Drag to left/right inside the box below, in order to view 360 degrees render-image.